Replace or Repair Damage Rack

Pallet rack damage is often caused by forklifts and pallets during normal warehouse operation. Pallet rack damage should be reported at once and replaced or repaired. Loads should be removed immediately when pallet rack damage is first spotted and the area roped off until the replacement rack is installed or the current upright is repaired. Even minor pallet rack damage should be inspected by a qualified rack engineer in order to determine its safety.

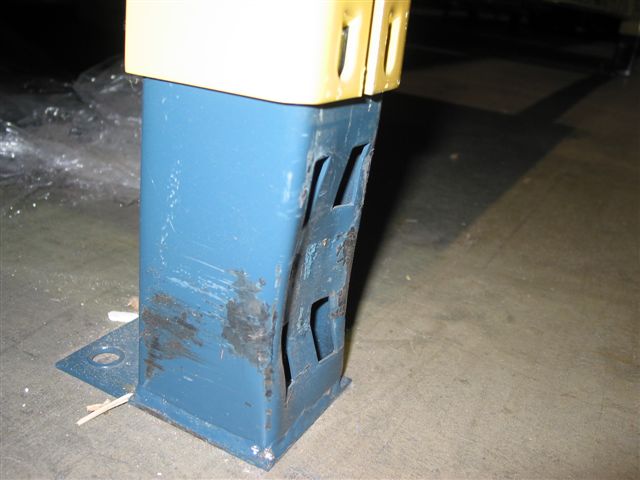

The photos to the right show examples of some pallet rack damage that has occurred from forklift abuse. ANY abrasions or denting should be taken very seriously and corrected. Pallet rack damage inspections should always be performed, but it is also up to warehouse workers to report collisions to pallet rack, no matter how small.

Warehouse personnel should be aware of procedures for reporting damaged pallet rack. They need to be advised of the importance and dangerous conditions that can exist for themselves and their co-workers if unsafe pallet rack conditions are left unreported and unrepaired.

PLEASE INSPECT PALLET RACK REGULARLY FOR DAMAGE.

No matter the size of your warehouse, pallet rack inspection should be a part of your operations. A professionally trained pallet rack inspector or engineer should perform visual checks and make sure all installations are up to current building codes.

It is every warehouse manager's responsibility to provide a safe workplace for employees and visitors. Since daily distribution center operations keep everyone busy, it should not stop personnel from ensuring the rack is damage-free.

Our engineers and Project Management personnel are trained for inspections and repair recommendations. All departments work together to find a rack repair solution that will cause the least amount of interruption to your facility.

UNARCO has engineered repair kits designed by racking experts with manufactured pallet rack parts to take corrective actions and bring your racking back up to spec.

Pallet rack repair options include both straight-leg repair kits and sloped-leg repair options. UNARCO can help with trained pallet rack repair specialists for added rack repair safety and also to help identify pallet rack damage in any warehouse or distribution center.

System Highlights:

Rack damage happens no matter how skilled the operators or how safe you run your facility. Make sure that warehouse personnel check for:

Beam and safety lock damage

Horizontal and diagonal bracing damage

Footplate damage - sheared or twisted baseplates or missing anchors

Column and post upright damage

Overloaded beams and frames beyond capacity limits

The structural integrity of the pallet rack must be maintained by not just the owner, but everyone in the warehouse. Warehouse operators should regularly inspect for damage and report any collisions with forklifts or product going into the rack. Any areas with damage should be unloaded immediately and flagged for repair or replacement.

In addition, warehouse personnel should not alter or reconfigure the pallet rack in any way without checking with a qualified engineer or racking manufacturer.

For more photos of Rack Repair systems, view the UNARCO Rack Repair Photo Gallery.

Safety First with Rack Damage

Whenever any visible rack damage is identified, all product needs to be removed from the rack until a qualified rack safety assessment can be made and a solution identified. It is always better to err on the safe side and report even the slightest damage after forklifts bump rack.

For more information and photos of pallet rack repair, visit our Pallet Rack Repair Portfolio or view our Pallet Rack Repair Brochure.